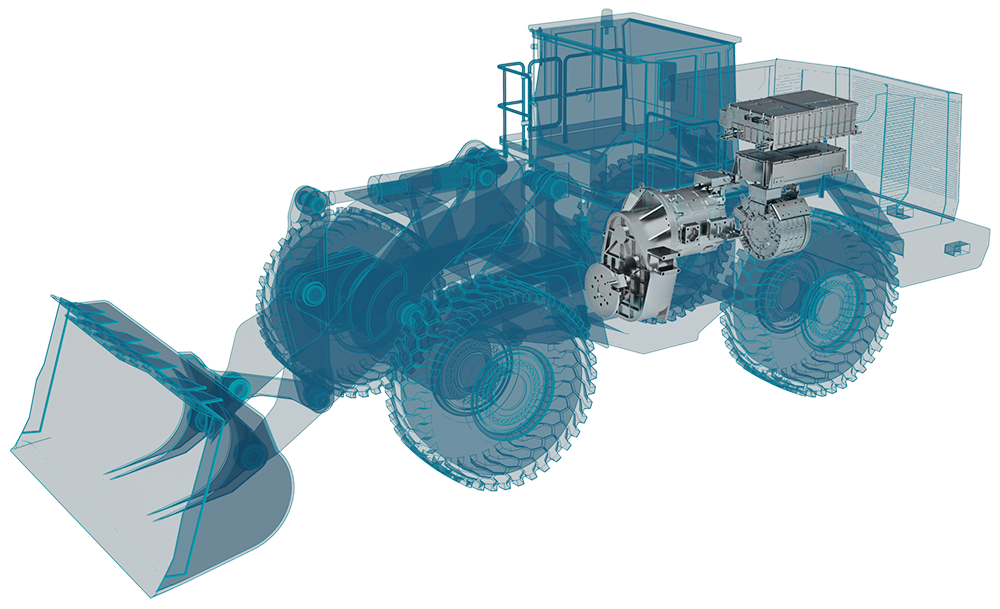

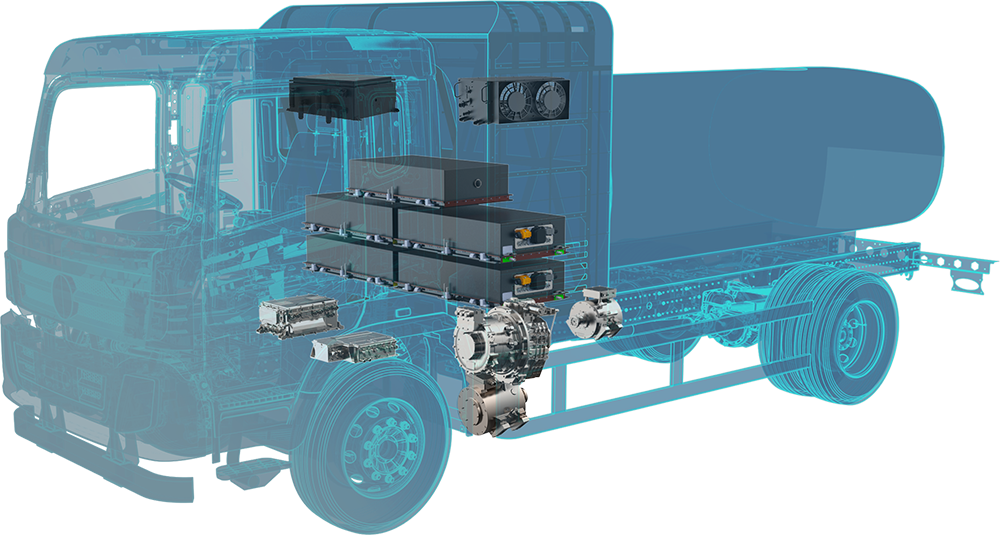

Ultra-low energy consumption,which can save the cost of a fuel loader per year;

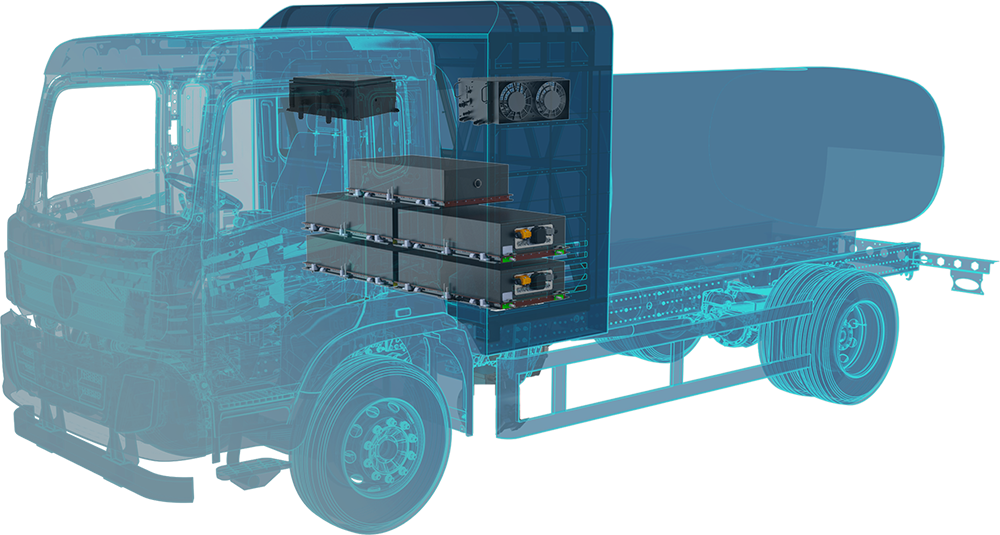

Equipped with large capacity LiFePO4 battery, which adopts double plug charging method, it can be fully charged within 1-1.5 hours, with a maximum endurance of 7-12 hours;

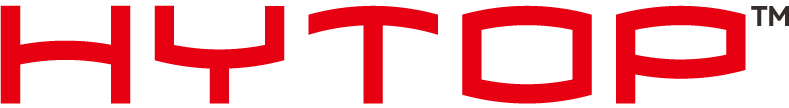

Leading key performance, accurate control, which can greatly improve system dynamic response and steady-state performance, to improve control accuracy, reduce energy consumption;

The motor torque fluctuation is small, without jerking sensation, with stronger reserve force, improved slope climbing, high peak power, and large short-term traction force.